The Process

Whether you already have something in mind or if you need a little help visualizing your future piece, it's important that we are on the same page every step of the way. This is how I make that happen.

Step 1:

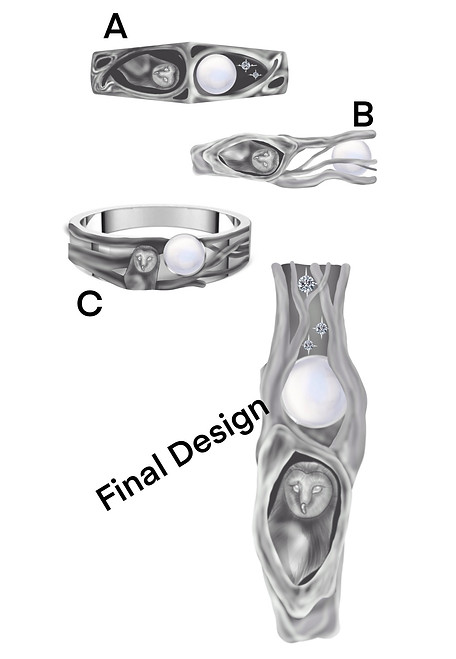

The first step usually consists of a handful of drawings. It's difficult to quote a customer a price without us both knowing exactly what the final product will be. Drawings allow my customers to visualize the finished product and they allow me to think about the structure and how everything will fit together. It's important to me that the jewelry I make lasts and it often takes some engineering to balance that requirement with some of the modern styles that people tend to prefer. Sometimes I land on a design that my customer loves in the first round of drawings and sometimes it takes multiple rounds. It is usually obvious when we land on the right design. After the customer chooses a drawing they like, I will price out a few options at different price points. The effort I put in and the workmanship is the same with every option, but depending on the materials used, the price can vary quite a bit. It is at this point when my customer can decide if they would like to go ahead and have me make the piece. If the customer wants to go ahead with it, I usually ask for a deposit that equates to around half the total cost.

Step 2:

This part of the process can vary, depending on the design and what I think would be the best way to build the piece. There are times when I will fabricate all the parts from bar stock or wire and sometimes I'll carve a wax, like I did with this owl ring. No matter what, I check in with my customer if there are any decisions to make along the way. Some people are interested in the process, so I'll send them pictures, even if I don't need their feedback. In the case of this owl, I sent pictures of the carving process and made sure she liked it before I cast the wax in white gold.

Step 3:

After casting, the metal needs to be finished. I use files, rotary burs, gravers and anything else that helps me give it the shine and detail it needs.

Final Product

After the stones are set, the final polish is put on and the customer is happy, the piece is done.